Every process in a food and beverage facility requires accurate measurement of material stored in large vessels, silos, or tanks. That makes the right level measurement system a key factor in successful production. While a wide variety of measurement technologies can be used, new non-contact frequency-modulated continuous-wave (FMCW) radar technology best meets the food and beverage industry’s need for hygienic components, measurement accuracy, and the ability to adapt to existing process connections.

Typical food and beverage processes include tracking inventory (of the feedstock or end product), batching, and blending operations, where precise knowledge of solids, powders, or liquids level is a must to guarantee quality.

Using a chocolate plant as an example, tracking inventory begins with measuring the filling of feedstock tanks. Trucks roll in and offload raw material, such as milk and cocoa. Tanks are periodically filled with solids or liquids and constantly drained. On the other end of the process, operators require an inventory of finished goods. This seemingly simple inventory tracking is in fact a critical materials management tool – enabling fiscal tracking of feedstock on one end and saleable goods on the other.

Between the incoming and outgoing inventory tracking is the actual chocolate-making process – where operators are using reactor tanks for heating, cooling, batching and blending. While these may seem like simple tasks that might go on in any home kitchen, obtaining accurate and precise level measurements in the process environment can be tricky.

First, the steam used for heating, cooling and blending creates a challenge for some level measurement tools, like build-up of vapours or dust. Also, some tools have a problem with providing a dynamic response. This is important because to produce a repeatable process, operators must be able to understand and monitor exactly what is occurring within the tank at all times.

During inventory tracking at the beginning or end of the process, the most important thing to operators is precision – accuracy translates into money. In the process environment, operators are most interested in repeatability, which can be even more important than accuracy. They want to know that the level instrument they use will behave the same way each time, giving them accurate, precise, and consistent temperature, pressure and level measurements. They are also interested in reducing losses (shrinkage) from the entrance to the exit of the plant.

COMMON TECHNOLOGIES

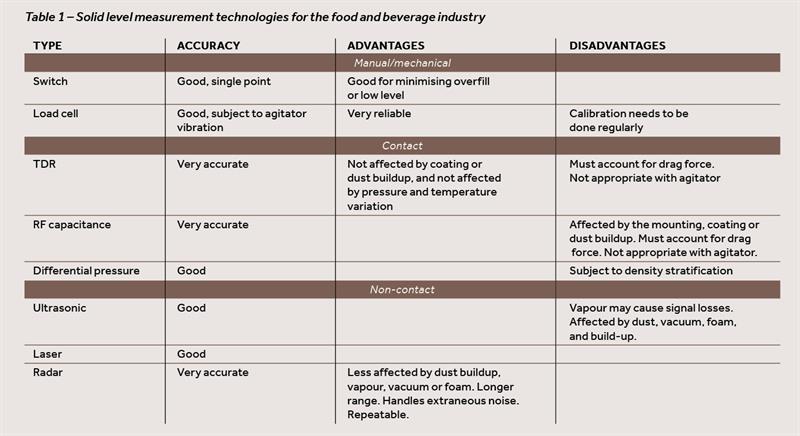

A wide range of level measurement technologies can be used in the food and beverage industry, including manual, contact, and non-contact methods. The most commonly used manual methods are manual gauging (bin bobs), switches and load cells. Contact methods include time domain reflectometry (TDR), radio frequency (RF) capacitance and differential pressure (DP) devices. Non-contact methods include ultrasonic, laser, or radar level meters. Nuclear gauges, widely used in other industries, are not considered a viable option for food and beverage products, due to the perception that their use could alter the product. See table, opposite, which compares the options.

Most options can be used to measure either liquids or solids: for example, grains, granular materials and flour used in food and beverage production. Bin bobs are usable only on solids.

Level measurement methods have varying degrees of performance accuracy and reliability. Each has a specification that indicates accuracy and repeatability – either so many millimetres (mm) or fractions of an inch. For example, bin bobs, ultrasonic and RF capacitance technologies may be in the range of inches (or multiple inches). Differential pressure technology primarily measures mass, converted to volume by density. It may be in the range of ½-inch accuracy when the density is accurately known, while some radar technology is far more accurate, with a ± 2mm/0.08in accuracy.

COMMON LEVEL MEASUREMENT ISSUES

The key issues that food and beverage plant operators face with level measurement devices are cleanliness, process build-up, the need to adapt to process connections and other obstructions, and dealing with rapid level changes.

Cleanliness is a key concern – operators must focus on material selection to ensure that components that come in contact with the material being measured are made of compatible materials with sanitary elements that are cleanable, so there is no chance of bacteria growth. For example, wetted parts may be made of Teflon to maximise cleanability. A 3-A approved sensor complies with all sanitary requirements.

Process build-up is another important issue that affects measurement accuracy. Going back to the chocolate example, temperature and viscosity differences as the chocolate goes from hot to cold may cause build-up over time. The viscous and sticky liquid chocolate tends to build up on any intruding measuring probes. This can lead to hygiene issues, increased maintenance costs and inaccurate readings.

Process connections may also cause measurement accuracy challenges. This is critical since process tanks blend materials and often have agitators, heating and cooling coils, and may have to adapt to existing fittings.

In addition, there are interfaces where some technologies – for example, differential pressure instruments – struggle to deal with stratification of temperature. Using the chocolate example again, there will be temperature stratification during heating of chocolate – product is hotter nearer the heater and cooler a distance away. Density stratification is another issue. A differential pressure device calculates level by dividing the pressure by the density of the product. If there is hot product at the bottom of the vessel and cooler chocolate at the top, the overall situation may be inaccurately represented. Errors may creep in when one wrongly assumes the density measured by the device is representative of the overall situation.

A final concern is the effect of rapid level changes on measurement devices. When an agitator starts or air is injected into a vessel, the overall level changes rapidly. Some technology may experience a lag between that change and the measurement device response. To achieve overall process control, operators must keep the process repeatable, with each batch handled the same way from process to process. Rapid response is extremely important for achieving this goal: operators must be able to track everything going on in a vessel and cannot afford a time lag.

NEW SYSTEM

While every measurement type has its pros and cons, new non-contact FMCW radar technology can be an excellent choice for many food and beverage applications. FMCW radar technology eliminates many of the issues experienced with other technologies, including moving parts and their associated maintenance issues, unreliability of measurements caused by build-up of material, and the effect of process connections. In addition, there is no intrusion into the process, so there is no risk of introducing any metal sensor parts into the process.

The primary benefit is that the FMCW radar emitter provides a continuous wave of frequencies. There is no gap – unlike with pulse radar, which emits short and powerful pulses and in the silent period receives the echo signals. This means FMCW provides more resolution of measurements and better reaction time. It offers extremely reliable measurement for rapidly changing processes while also keeping measurements accurate. Pulse radar may be an excellent choice for inventory applications where there is not a rapidly changing environment, but FMCW is the better choice for more complex mixing, blending and batching processes that require process control.

For example, Krohne developed an FMCW level transmitter specifically designed to meet food and beverage requirements, especially those related to cleanability, unique process connections and typical ranges. This model has 3-A sanitary certification and tri-clamp connectors, hazardous area certifications, and meets material specifications for food and beverage industries.

The new technology also has a more focused beam: energy is concentrated in a smaller area with less reflection, making it more efficient with foam or steam.

Another significant measurement benefit with the new technology is fewer dead bands or dead zones, which are a fundamental issue with most frequency-based electronic measurements. With these device types, a portion of the range will always be a dead zone. Noise will be generated at the very top of the tank where the pulse leaves the antenna and goes into the vessel. In addition, the solid bottom of a stainless steel vessel creates a strong reflection. When the product drops too close to the bottom of the vessel, the signal generated by the reflection of the fluid is not strong enough to be differentiated from the strong signal created by the bottom of vessel – and the position of the fluid level can be lost.

In low-frequency devices (such as ultrasonic and pulse radar) these dead zones at the bottom and top of the vessel can range from between 6in to 1ft. For smaller 6ft-tall stainless steel cylinder tanks, if there are 1ft dead zones at top and bottom, there is only a 4ft measuring range! With the smaller antennas of the new FMCW level transmitter, dead zones are reduced. The smaller antenna size means the antenna is flush to the tank, so a wider range of measurement is possible. In addition, the PEEK-based antenna was designed to meet all food and beverage hygienic requirements.

BOX: Chocolate application

The new non-contact FMCW radar technology has been used successfully at several chocolate-making operations to improve stock management through automated level measurement. The technology gives reliable and accurate readings despite viscous, sticky liquid and moving product surface. It gives continuous, precise readings of the liquid chocolate level right up to the process connection. The radar can measure agitated product surfaces with an accuracy of ±2mm/±0.08in.

For example, a manufacturer of a range of confectionery products stores six different kinds of liquefied chocolate in double-bottom temporary storage tanks. The liquid chocolates are continually stirred by a slowly rotating agitator. In addition to monitoring each type for the production line, operators wanted automated replenishment of tanks if the level falls below a set value.

Another industrial bakery was producing chocolate buns using liquid chocolate stored in a tank. For ten minutes every four hours, a rotating scraper removed the chocolate from the tank walls. The moving product surface resulting from the action of the scraper was affecting measurement accuracy. In addition, the company wanted an automated measuring solution to manage stock and reduce manual workload.

Both companies opted for the new FMCW radar technology, which has an 80GHz transmitter designed for liquid applications with hygienic requirements. The device continuously measures the level of the liquid chocolate and automatically transmits values to the control room. The measuring technology optimises the supply inventory and reduces maintenance and production costs at both plants. At the multi-tank plant, the device replenishes the tank whenever the chocolate level falls below a certain threshold.